Strain gauge balances and instrumentation: Precise – stiff – reliable

Using the latest technology available the, well-known family of RUAG block-type balances and specialized loads instrumentation, has been optimized for precision, stiffness and high loading.

RUAG's instrumentation specialists are actively engaged in serving you promptly and efficiently. This means that all our experience, engineering skills and workmanship flow timely into your measurement needs.

Your advantages at RUAG

Contact

RUAG AG

Schiltwald

6032 Emmen

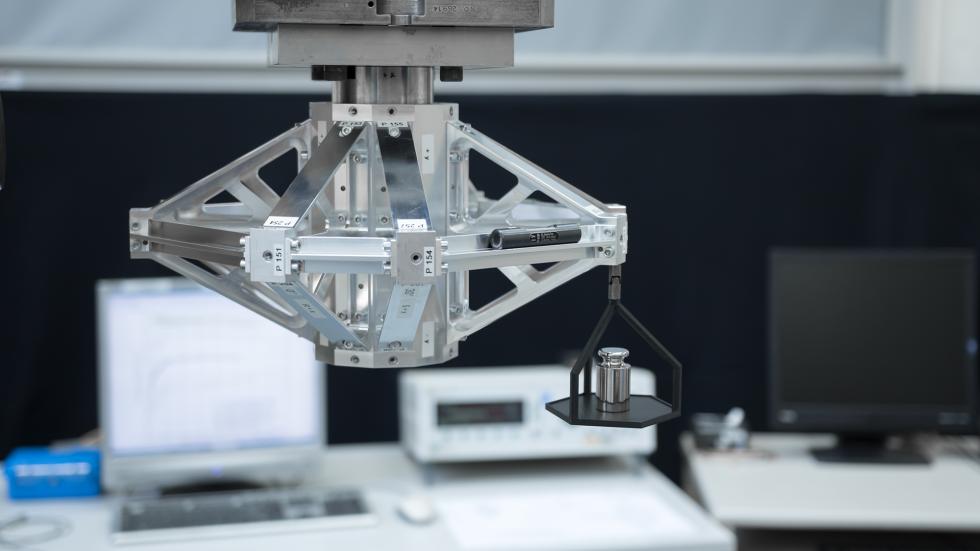

Balance family optimized for precision, stiffness and high loading

The basic and well-proven design concept has been much refined using today’s available tools for design optimization.

Strain gauges at carefully selected and designed locations on the balance measure the strain produced e.g. by aerodynamic loads and the model weight on the metric side of the balance.

Theoretical, computational, and experimental analyses led to design features which reduce the interferences between the load components, diminish local and overall deformations, and increase the safety factor by limiting local stress concentrations in the critical areas. The material of the balance, its conditioning, and the strain gauges are chosen to minimize hysteresis and creeping behavior and thus to further reduce error sources. Since the balance is also suited for measurements with highly dynamic loads, extensive fatigue analyses and testing were performed to ensure the required number of load cycles.

The highly linear characteristic of the balance allows the use of a linear calibration matrix which considerably simplifies data processing and thus improves test performance. The accuracy can be further improved (better than 0.03 %) by using a second order nonlinear matrix which additionally considers statistic criteria to eliminate linear dependencies and insignificant terms.

In addition to our block balance families, we provide customized solutions such as multicomponent rotating shaft balances inclusive data transmission, wing/wheel balances for car models or balance crossings.

Balance selection

Balance selection is a decisive step during the definition of an experiment, be it in the wind tunnel or any other test facility. An inappropriate balance selection either causes overload conditions possibly resulting in damages to the precious balance or the absolute measurement precision is necessarily reduced as the balance range is not utilized optimally.

To get best measurement accuracy the values defined above should be close to one but must never exceed one. In order to simplify the critical selection process, use the selection tool of the Excel Spreadsheet to download.

For your convenience, all RUAG balances are also available for rent – an attractive option for short projects within a tight timescale.

Instrumentation

The need to acquire precise physical properties such as the measurement of strains, pressures, temperatures and accelerations are applied in many fields other than wind tunnel testing.

Experimental structural testing using strain gauges is necessary in a wide range of applications from aircraft and sub-assemblies down to individual components such as wind turbines, buildings, machine beds and many others. These tests enable the engineers to compare the experimentally acquired data with the predicted stress or fatigue results from design calculations.

The health of train wheels is assessed at focal points of the Swiss railway network through analysis of the loading signals of the train running over the rail at normal speed. This harsh environment – exposure to extreme temperatures, humidity, vibrations etc. – poses many challenges and can only be overcome by clever design and meticulous handicraft.

RUAG's state-of-the-art sensor and measurement systems ensure the realism and precision in testing conditions.

- Engineering and consulting

- Setup / operation of measurement chains, data acquisition system, data processing, data analysis

- Determination of measurement uncertainties

- Rental of measurement equipment

Calibration

Test sequences per the ISO 9001 standard require measurement systems and measuring chains to be calibrated periodically and proof of traceability to national standards. This service – used in-house at RUAG’s wind tunnels – is also available and provided to interested parties from other industrial sectors.

- Calibration of electrical signals, temperature, pressure, loads, torque

- Quality management ISO9001:2015, AS9100:D technically equivalent to fprEN 9100:2016

- Determination of measurement uncertainties

Downloads

Would you like to learn more about our services? Here, you can download various additional information.

Further reading material

SUITABLE TOPICS FOR FURTHER READING

Aerodynamik Home

Test Benches